Talk with our teams for your applications

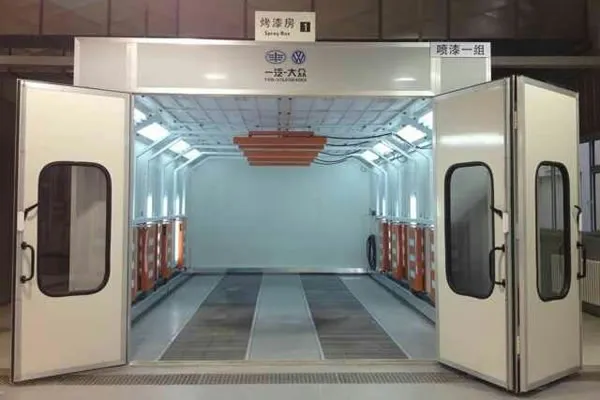

Radiant Heater of Spray Booth

Radiant Heater of Spray Booth

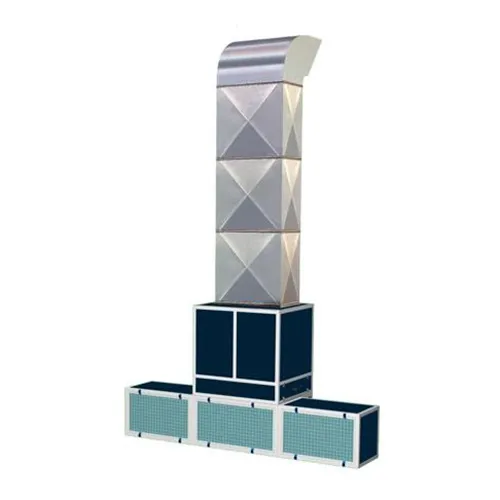

The high temperature far-infrared radiator with wide wavelength range is a high-end technology, which synthetically applies the thermal power, far infrared, electromagnetic field, and thermal photon beam for the heat treatment of objects being processed.

The objects to be heated are directly radiated without the media conversion. Then, any object can be penetrated rapidly, and the coating is allowed to be solidified from the inside to the outside. This method is different from the conventional way that the fuel-oil type paint spray or the ordinary electric-heating type paint spray adopts the outside-in drying method. Therefore, the electro-thermal conversion efficiency reaches over 95%.

An experiment proves that this radiant heater of spray booth requires the power consumption of only 0.2-8 degrees for the paint spraying of the partial or entire car. This product is widely applicable for the medium and low temperature of drying process at the ambient temperature of at most 80 degrees Celsius.

Features

- The radiant heater of spray booth adopts the purely-physical drying process. In this way, both oxygen and moisture in air will not be consumed, and no harmful gas or substance will be discharged. Furthermore, no noise will be produced. Hence, this machine is made in full compliance with the environmental requirement.

- It is pretty safe to use our radiant heater of spray booth. Firstly, this product mainly utilizes the far infrared radiation for heating, rather than the traditional method of air heating. It can well protect the paint surface from the secondary pollution resulted from the air flow. Secondly, the radiator is unique in its health care effect, which allows the working environment of operators to be greatly improved. Thirdly, this machine eliminates the possibility of a fire disaster caused by the heating of fuel oil.

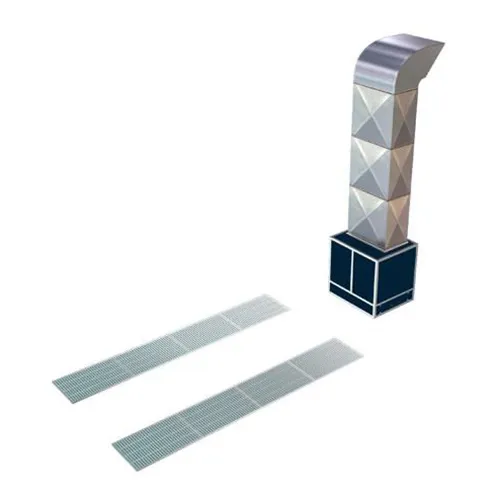

- Due to the adoption of a flexible heating method, the radiator heating system spends only 6-20 minutes each time on paint spraying. The vehicle body is only needed to be naturally cooled. There is no need to wait too long, or adopt the integrated type curing operation. When the vehicle is required to be partly processed, very low energy will be wasted. Thus, the radiant heater of spray booth can work highly efficiently.

- The thermal photon beam produced by this machine can be uniformly distributed on the radiated surface. In addition, both moisture and solvent in oil paint will be firstly evaporated during the curing process. Different from the conventional product, this radiant heater of spray booth will not produce any bubble, pinhole, wrinkle, crack, and some others on the dried surface of the paint coating. Furthermore, the putty, paint and other substances features strong adhesive force, high toughness, great integrity, superb drying effect, and high rate of thermal energy conversion.

- On basis of the physical radiation principle, the irradiated material will not cause any chemical reaction, and its molecular structure will not be changed.

- The shorter the wavelength, the stronger the penetrating power will be. The irradiated material is heated from the inside to the outside.

- This radiant heater of spray booth features environmental protection, energy conservation, and no pollution. The heating system of the radiator combines the group control with the integral control. A point-to-point heating method can be utilized for the curing of the part of the vehicle body.

Depending on the above-mentioned advantages, the radiant heater of spray booth can not only dry the paint surface and timber floor, but also realize a high level of drying of various electronic components. It succeeds in replacing the traditional drying machine in plenty of industries, so as to realize the significant reduction of production cost.