The bulldozer painting line is designed by our company for Tianjin Yishan Heavy Industry Company.

Customer Requirements

- Firstly, we are required to accomplish the task of painting 6,000 bulldozers each year. Moreover, we provide both dimension and site drawings.

- Secondly, our designers can arrive on site for observing the process defect and site location. Then, the suitable coating line can be custom-made. The design process is described as follows.

How to Paint the Surface of Spare Parts of Bulldozer Products

On-line → Shot blasting treatment → Shot blasting and filling manually → Cleaning (dust removal in use of compressed air) → Spraying the primer → Leveling → Spraying the second layer of paint → Leveling → Drying → Forced cooling → Inspection → Off-line (serving as an assembly line)

How to Paint the Surface of the Entire Bulldozer

Surface cleaning (water cleaning) → Drying of water → Filling the putty → Polishing → Shielding the workpieces → Checking the surface → Spraying the surface finish → Leveling → Drying → Natural cooling → Spraying the second layer of surface finish → Leveling → Drying → Natural cooling → Spraying the finishing varnish → Drying → Natural cooling → Inspection (as an assembly line)

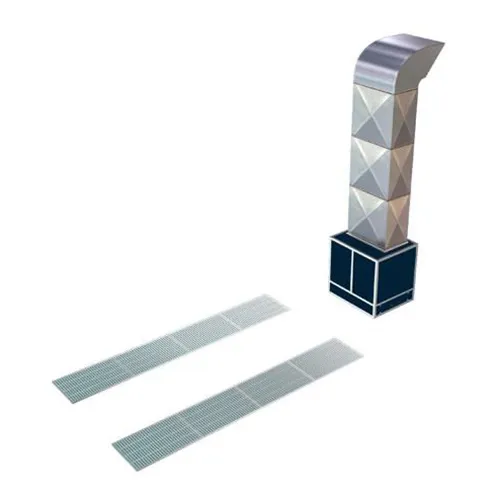

This bulldozer painting line helps reduce manpower for the transportation of workpieces. It is designed with the trolley moving on the ground, as well as the track chain placed on the ground. The whole machine features the upright and arc structure, which makes our clients pretty satisfied.

This example case is ideal for use in machinery or carpentry manufacturing enterprises.

Bus Painting Line in North Neoplan Company

Bus Painting Line in North Neoplan Company Automotive Sheet Metal Spray Line in Beijing FAW Group

Automotive Sheet Metal Spray Line in Beijing FAW Group Spray Coating Line Used for Industrial Parts in Cameroon

Spray Coating Line Used for Industrial Parts in Cameroon Automotive Spray Booth in Canada

Automotive Spray Booth in Canada-

Large Size Bus Spray Booth in Peru

Large Size Bus Spray Booth in Peru -

Bulldozer Painting Line in Tianjing Yishan Company

Bulldozer Painting Line in Tianjing Yishan Company -

Large Spray Booth in India Suzlon Company

Large Spray Booth in India Suzlon Company -

Other Projects

Other Projects

Talk with our teams for your applications