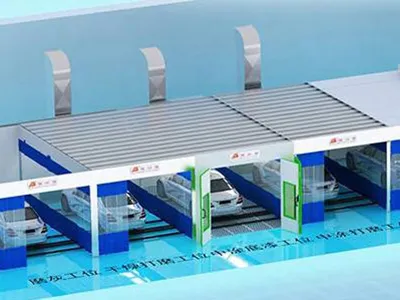

Talk with our teams for your applications

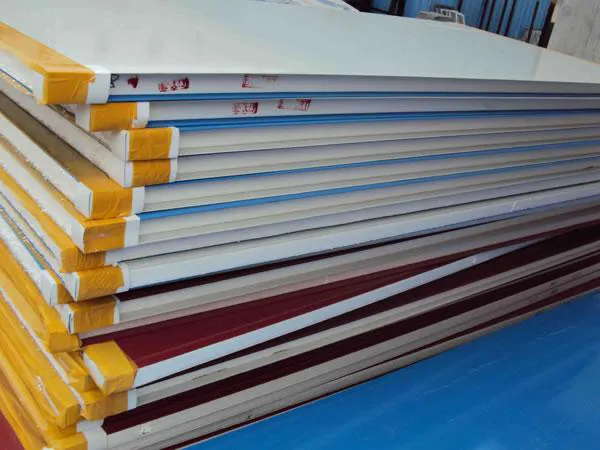

Our EPS panel is produced by introducing both equipment and technology from Australia. The molding is carried out only once. As a fire-resistant plate, this product features light weight, vivid colors, outstanding thermal insulation properties, and low coefficient of thermal conductivity. Its service life reaches up to 25 years. The state-of-the-art technology makes sure that the entire house is firmly sealed. It effectively avoids heat loss as well as the intrusion of dust from outside.

This pressure lock can provide all operators with a high level of security. Once the air overpressure occurs in the room, our product will automatically open the emergency exit.

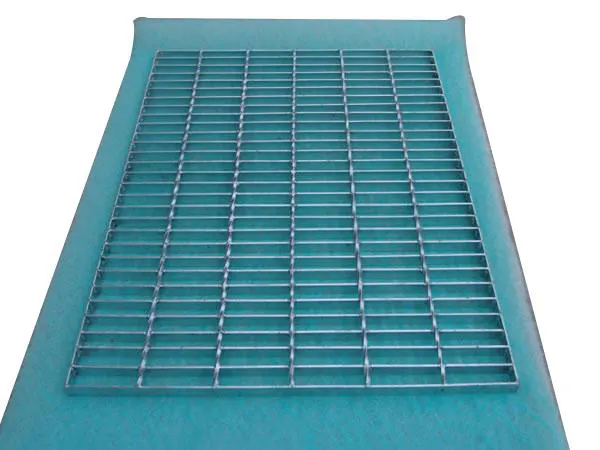

This floor grille is made of galvanized steel or steel material. It features high durability and decent appearance. The metal grating is available in different sizes. It is applicable for spray booth, prep station, painting line, and other industrial equipment sets.

Our centrifugal fan is an external-rotor type product with class F insulation. It is made by adoption of Siemens technology, providing low noise and great air quantity.

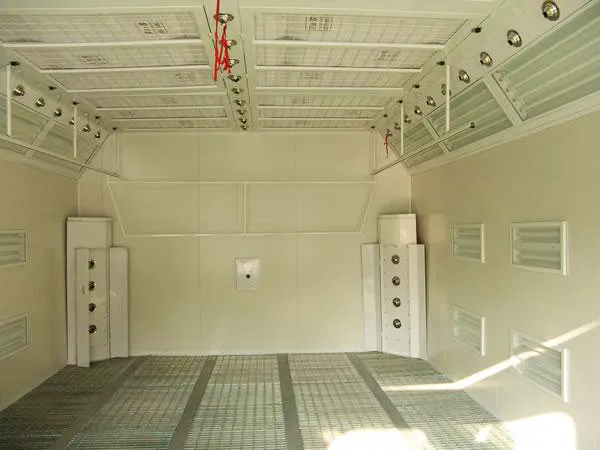

This centrifugal fan allows the average air velocity in the operating area to be approximately 0.3m/s. In this way, the requirement for shaping the paint film can be well guaranteed to increase the utilization rate of paint. Simultaneously, the required air cleanliness can be achieved to secure the health of all workers in the operating area. Furthermore, the positive pressure inside the room can effectively prevent dust from seeping into the operating area. Accordingly, the quality of spray paint is guaranteed.

This DKF series centrifugal ventilator is a derivative of YDW series low-noise centrifugal fan. It can meet the needs for any air quantity or air pressure during the design and selection of air conditioner.

The DKF series centrifugal ventilator is characterized by high efficiency, low noise, large air quantity, low rotational speed, light weight, and some others. It consists of the DKF series forward curved impeller type, the DKF series backward curved impeller type, the logarithmic spiral casing, as well as the arc, streamlined air inlet, among other components.

Our product is fully made of galvanized sheets. Its framework is adjustable. The belt pulley can turn left and right for use. This DKF series centrifugal ventilator is an ideal matching product in such industries as air conditioning, purification, paint spray booth, and refrigeration.

Our 4-82 series centrifugal ventilators are independently developed by integrating the merits of manufacturers from home and abroad. They can meet the special requirements for huge air quantity and low head in air conditioning industry.

This series product offers such prominent characteristics as wonderful performance, high efficiency, gorgeous appearance, compact structure, stable operation, convenient maintenance, and more. Therefore, it is especially ideal for all kinds of horizontal type air conditioning units.

This BELIMO-automatic air vent is imported from Switzerland with original packaging. It is vertically mounted during the paint spraying process. In the paint curing process, our product will automatically form a 90-degree opening angle to produce internal circulation. It offers a long holding time, as well as great reduction of both oil and electricity.

This water-borne painting system adopts 36 pieces of ceiling nozzles as well as 2 centrifugal fans with the power of 1.5kW/set, for the purpose of drying water-based paint. In addition, it comes with 2 sets of air drying systems with the power of 0.18kW/set. These two systems are separately controlled.

Our spray booth filter is a unique product with large area. The whole system makes use of the world's advanced technology. As its core part, the filter screen is made in Italy. It allows the air in the curing booth to be uniformly filtered and purified. Also, it makes sure that both air velocity and pressure in the operating area are in the best condition during operation. Simultaneously, this product creates a pretty clean working environment for our painting technicians, which can meet the maximum demand for a high level of spraying and curing.

Our spray booth burner takes advantage of the light oil burner, which can not only significantly increase the utilization rate of energy sources, but also guarantee no pollution to environment.

Its matching heat exchanger adopts the superior-quality stainless steel plates of high temperature resistance. Thanks to scientific design and fabrication, the heat transfer efficiency reaches over 85%. The remarkable features include large heat-transfer area, complete combustion, high thermal efficiency, as well as high safety and reliability.

This air heater takes only 5 or 6 minutes to increase the temperature from 20 degrees Celsius to 60 degrees Celsius by means of the heat cycling of fresh air. This allows the energy to be saved. Additionally, the heated air is uniformly distributed, and offers considerable quantity of heat per unit volume, which provides a reliable guarantee on the consistency of all temperature points in the room.

Furthermore, our product overcomes the shortcoming that the pneumatic actuator is prone to failure. Then, the use of electric actuator gives much higher reliability. By adoption of various types of paint mist filtering devices and adsorption systems, the exhaust emissions can be pledged to reach the national standard.

Our control panel acts as the control center of the entire curing booth. All its operation and control elements are the supreme-quality electronic components, which are produced by the selected world-famous manufacturers. Owing to meticulous design, the entire system offers stable performance, and much convenience for serving our customers.

In use of the control panel, each control state can be accurately set up. The program-control device is able to precisely display the temperature and drying time inside the curing booth. What's more advanced is that the automatic spraying and curing process at constant temperature can be carried out under different temperature. Moreover, the whole process is set to be completed for only once.

-

- Diesel Oil Burner of Spray Booth During the drying process, the oil nozzle of the burner can make fuel oil be atomized, which allows flame to be formed with the help of electric spark.

-

- Gas Burner of Spray Booth In the paint spraying process, the gas nozzle of the burner serves to eject the fuel gas. After electric spark ignition, flame can be formed.

-

- Radiant Heater of Spray Booth The high temperature far-infrared radiator with wide wavelength range is a high-end technology, which synthetically applies the thermal power, far infrared...

-

- Infrared Lamp Heater of Spray Booth The infrared lamp heater of spray booth is widely applicable for the industrial heating or drying process.

-

- Fin Heater of Spray Booth The fin heater of spray booth adopts a variety of materials including high-quality stainless steel, modified protactinium oxide powder, high-resistance electro-thermal alloy wire, stainless steel...

-

- Hot Water and Steam Heater of Spray Booth The hot water and steam heater of spray booth refers to the finned-tube air heat exchanger. It is mainly used for heating air in the drying system...