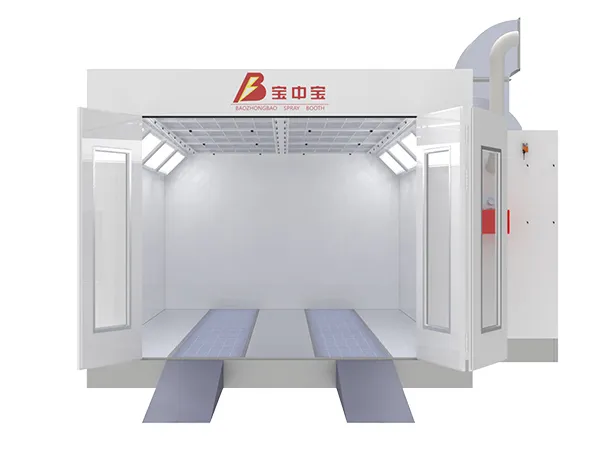

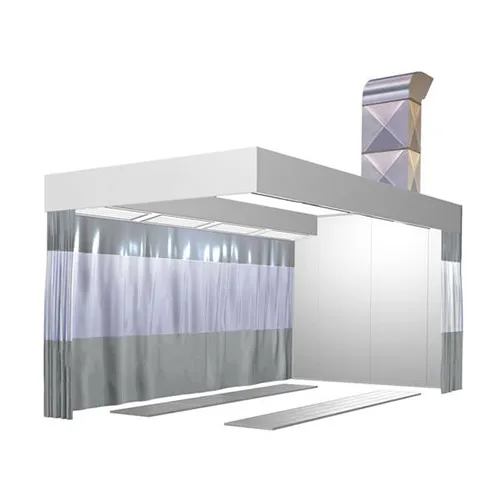

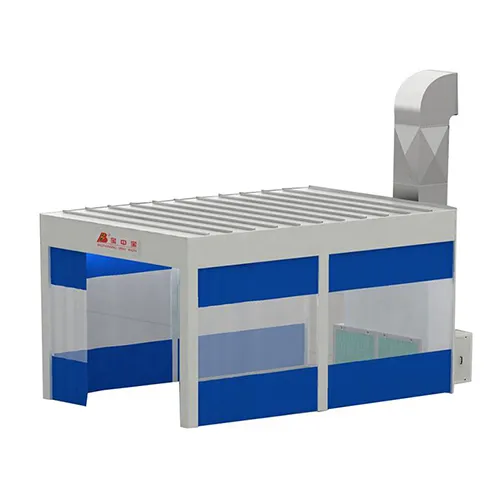

| External Dimension (mm) | Internal Dimension (mm) | Gate Size (mm) | Total Power (kW) |

| 12146×6096×4600 | 12000×4500×4000 | 3300(width)×3900(height) | 34.5 |

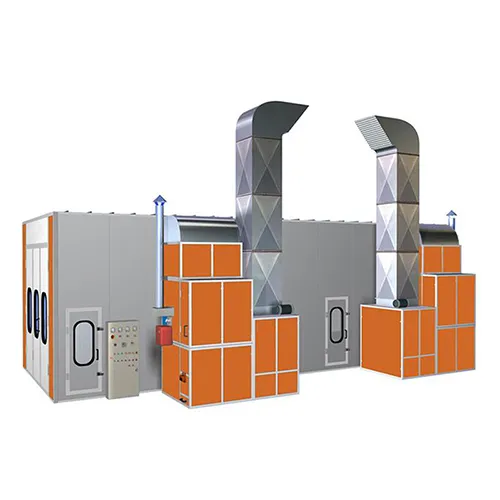

| Trench | Two rows of trench are used to exhaust the air. Each row of the trench has the dimension of 10000×840mm (L×W). In addition,the trench is covered with the galvanized floor grating. |

| Front Door | Our 12m bus spray booth is installed with three single doors. The frame of the door adopts the folded edge which is made of the coated steel plate. Moreover,the EPS board is used as the wall panel. |

| Service Door | There are totally two service doors with the dimension of 700×2000mm (W×H). The door is mounted with a pressure lock. |

| Chamber | 1. The steel reinforcing rib is mounted in the middle of the wall.

2. The ceiling is installed with the steel composite beam.

3. Moreover,the insertion type flame-retardant polystyrene insulation board is adopted. The wall board is 70mm thick and 1150mm wide. The colorful steel plate is provided with the thickness of 0.426mm.

4. The roof panel is assembled by the premium-quality steel plate. |

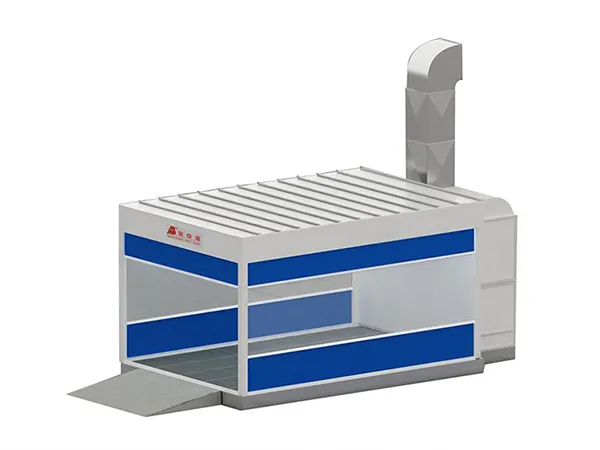

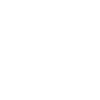

| Cabinet | 1. The air is supplied from the side,and discharged from the back.

2. The framework is made of the coated profile.

3. The outer layer is the externally painted plate. The inner layer is the galvanized steel plate. The middle layer gives the function of thermal insulation. |

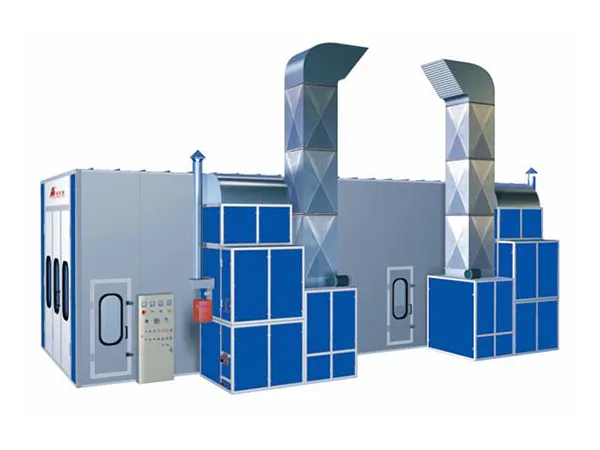

| Air Supply System (2 sets) | 1. Each set has two double-inlet centrifugal fans. Totally four double-inlet centrifugal fans are equipped to supply the air. The model and technical parameters of the fan are described as follows.

Model:YDW4.5L

Power:4.0kW

Flow Rate:12,500m3/h

2. The fan cabin is formed of the coated profile as well as the coated steel plate. |

| Air Exhaust System (2 sets) | 1. For discharging air,two 7.5kW centrifugal type exhaust fans with large impeller are configured. The model of the fan is 4-82. The motor is installed externally. Moreover,this fan is driven by a belt,and has an air capacity of 21,000m3/h.

2. The exhaust cabin is constructed from the coated profile and the coated steel plate.

3. The exhaust duct is composed of the premium-quality galvanized steel plate and the professionally made flange. It is also designed with a manually adjustable damper. |

| Heating System (2 sets) | 1. Our 12m bus spray booth is configured with two sets of Riello-brand G20 type burners. The maximum heating value reaches up to 400,000Kcal/h.

2. The heat exchanger is made from reliable-quality SUS304 stainless steel by adoption of argon arc welding technology.

3. The heat generator has received a spray finish.

3. The electric actuator is imported from Switzerland with original packaging. It allows the automatic changeover of spraying and curing to come true.

4. The highest temperature reaches 80 degrees Celsius. |

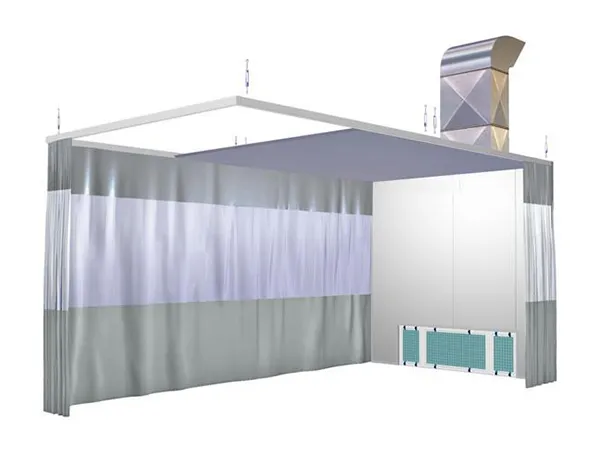

| Filter System | 1. The intake air is primarily filtered.

2. This 12m bus spray booth makes use of three different filters,including the high-class ceiling filter,the glass fiber filter,and the activated carbon being placed horizontally. |

| Lighting System | 1. Side of the Ceiling:16 groups x 4pcs=64pcs 18w LED tubes

2. Side of the Waist:10 groups x 2pieces=20pcs 36W LED lamps

3. The electronic ballast is provided for exclusive use. It can be connected with two light tubes.

4. The intensity of illumination reaches 800Lux. |

| Electric Control System | 1. A push-button face plate serves to control this system.

2. The main circuit features multi-protection.

3. The system makes use of the lighting switch,temperature and time settings,room-temperature or constant-temperature paint spraying,paint-curing switch,emergency stop switch,fault alarm,timer,temperature limiter,and more. |