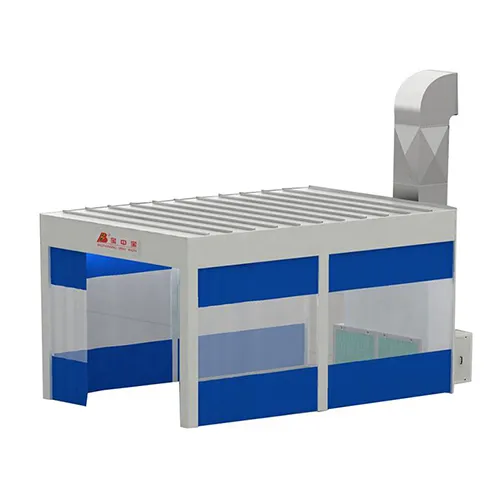

Multifunction Prep Station

Multifunction Prep Station

Our multifunction prep station is also called multi-station prep station.

Working Process

- After a car enters the waiting area, 4 wheels of the car are guided into four removable trolleys.

- The car should be moved to the required area in accordance with the work order. Then, different working procedures must be finished, including the metal plate processing, dust grinding, drying, primer, shielding, surface paint, drying, polishing, assembly, and more.

- The car moves across all working areas, which is completed with the help of the trolley on the track.

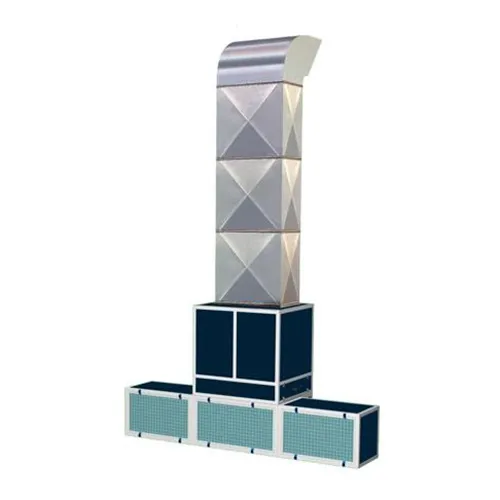

Product Structure

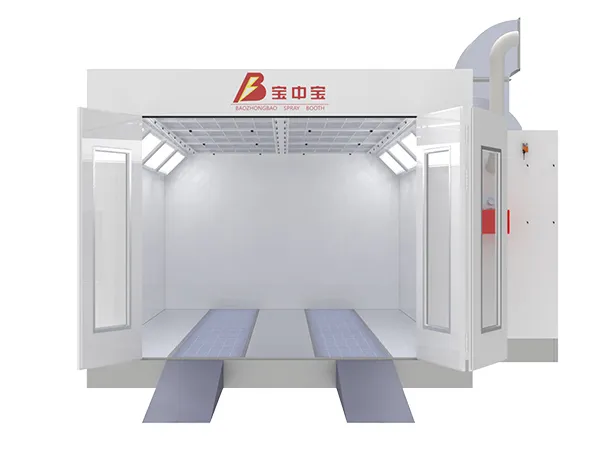

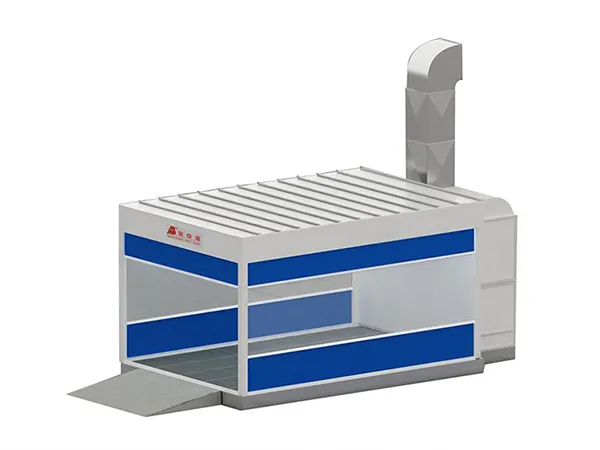

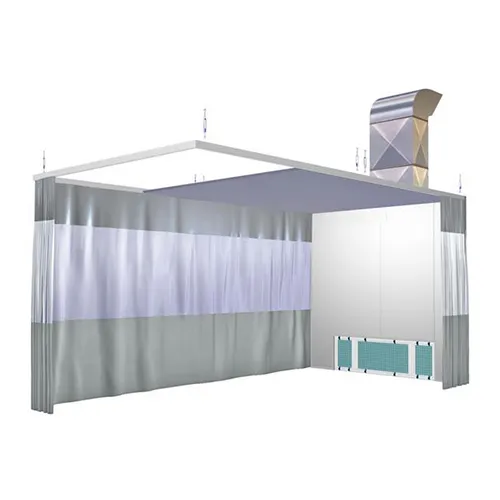

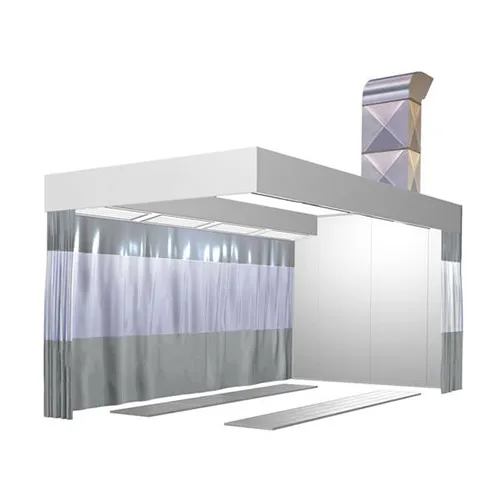

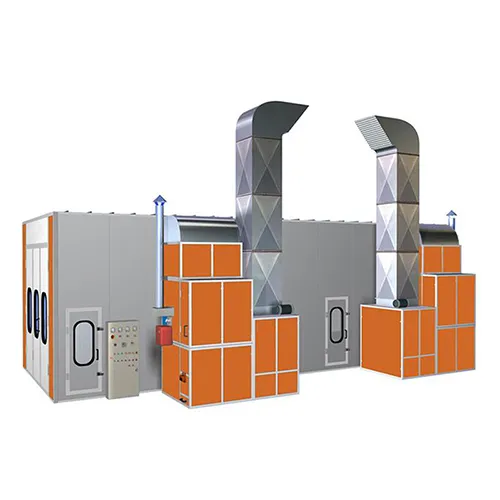

- This production line makes use of the spraying or curing structure that can work independently. All side walls of the surface paint spray booth and paint curing booth are composed of removable doors. The car depends on the removable door to pass through.

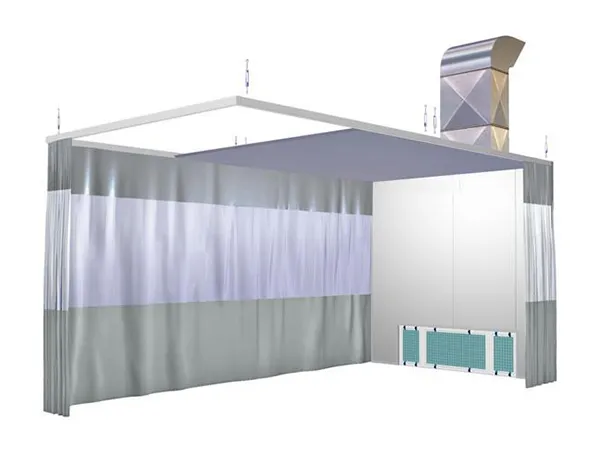

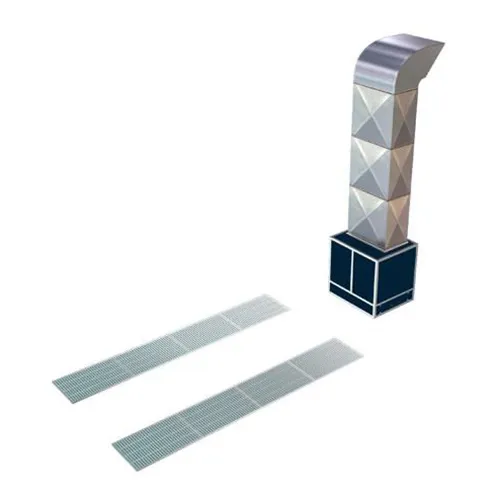

- This multifunction prep station comprises the paint spray booth, paint curing booth, floor rail, and the removable trolley. Optional configurations include the prep station as well as the infrared paint curing system.

- The paint spray booth and paint curing booth are connected in parallel. Both ventilation system and heating system are placed rearwards.

- With the help of the removable trolley, the car can successfully shift from the prep station to the paint spray or curing area.

- The removable door of our multifunction prep station is categorized into three types, including the push-pull type folding door, the vertical type hanging door, as well as the turn plate type hanging door. Among them, the hanging door features the automatic lifting structure.

- If the vertical type hanging door is selected, the installation space must be no less than 5800mm.

- As an option, a small-sized paint curing boot can be installed for the paint spraying or curing operation of spare parts.