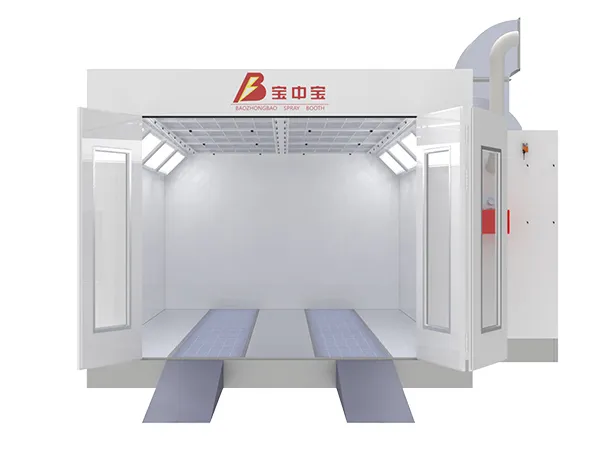

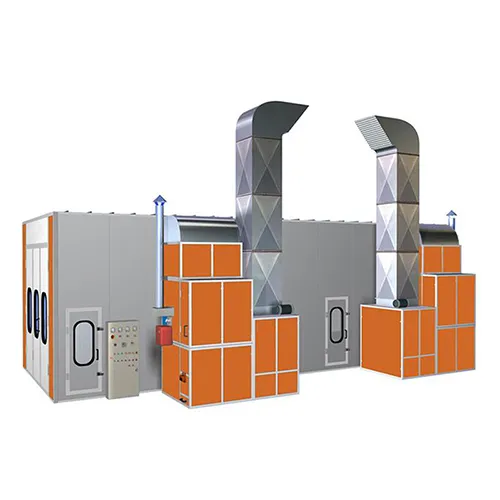

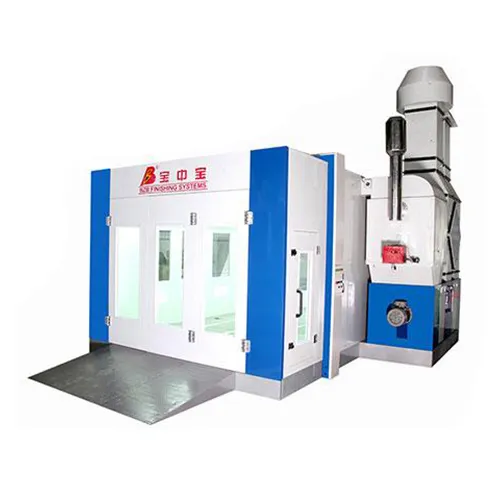

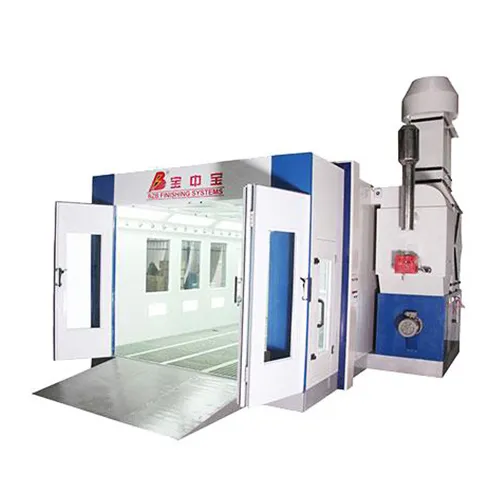

Paint Booth & Finishing System for Your Applications

List of Configurations

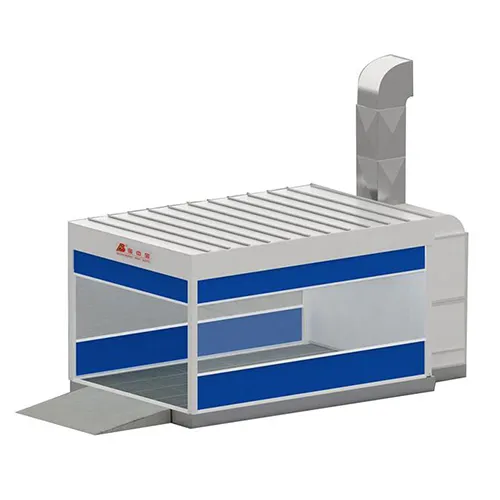

| Internal Dimension (mm) | 6400×4000×2650 | External Dimension (mm) | 7650×4106×3430 (excluding the ramp) | Total Power | 6.5kW |

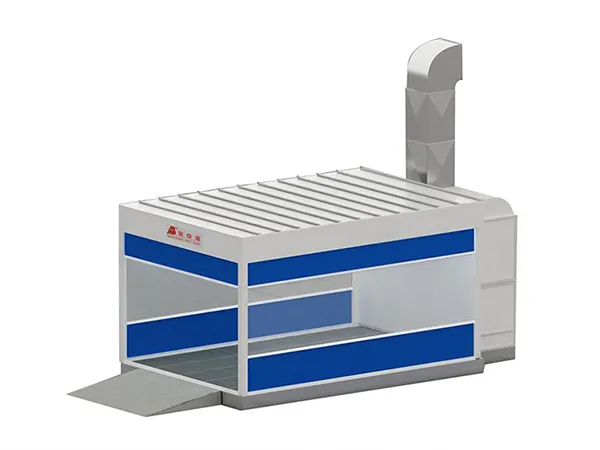

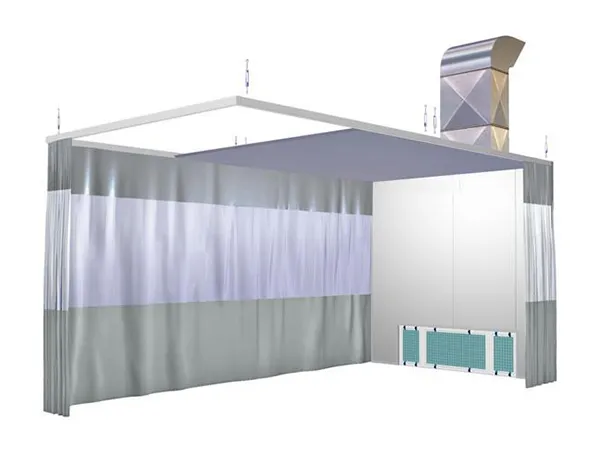

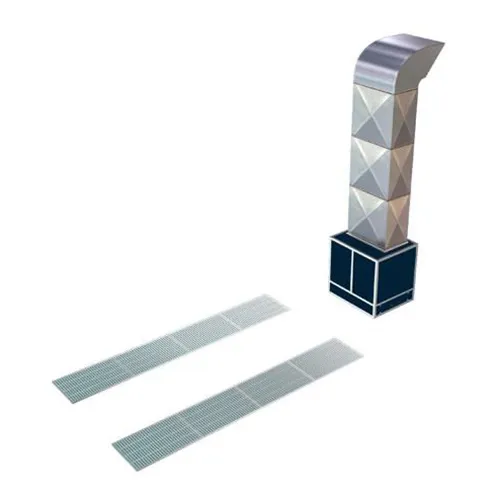

| Cabin System | 1. Ceiling: The plenum chamber adopts the cold-rolled steel plate which is subjected to such processes as bending, spraying, and molding. The roof panel utilizes the galvanized steel plate, which is hoisted in use of steel rope. 2. Front and Both Sides: Our 6400 prep station utilizes the flexible PVC curtain, which slides on the predetermined aluminum alloy guide rail. 3. Rear Side of the Wall: The EPS insulation board of 50mm thick is adopted. 4. Basement: This 6400 prep station uses the integrated anti-corrosion platform for air exhaust. The walking platform is composed of the diamond plate and high-strength floor grille. The overall structure is lightweight, innovative and beautiful. Its strength, rigidity, stability, and shock resistance are pretty good. 5. Ramps: Two ramps are formed by the embossed plate of 3.0mm thick and 600mm wide. | ||||

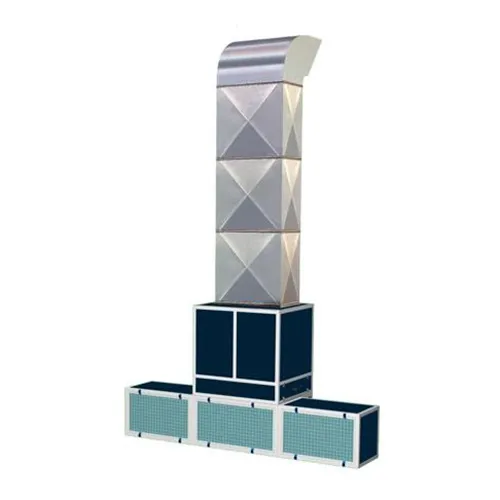

| Circulation System | 1. The air is exhausted through the basement. 2. Centrifugal Fan: By adoption of Siemens technology, the YDW series double-inlet centrifugal fan is formed of compression-molded galvanized plates. This fan gives great air quantity, low noise, and superb temperature resistance. It is manufactured by a dedicated fan factory. Detailed Parameters Model : YDW-5.6S Air Capacity: 15,000m3/h Total Pressure: 800Pa Rotational Speed: 900rpm Power: 5.5kW Quantity: 1 set 3. Exhaust Cabin: The framework is constructed from section steel. The cabinet body is assembled by painted steel plates, featuring stable structure, beautiful appearance, and convenient maintenance. | ||||

| Air Purification system | This system adopts the Italian made exceptional-quality filter screen. The filter has multiple layers. It is placed at the bottom of the plenum chamber, and supported by the roof mesh. With C-shaped steel structure, the roof mesh causes no corrosion. It can be replaced easily, and effectively catch the dust particle with its diameter of more than 5μm. | ||||

| Environmental System | 1. The first floor filter is mounted under the grille of the return air duct, for catching large dust particles. 2. The second fiberglass is placed inside the exhaust cabin, for seizing the residual granules. | ||||

| Lighting System | 1. Ceiling Light: 6 sets*4pcs=24pcs 36W Philips Lamp 2. The lighting sets provide the room with soft and uniform light. 3. The ballast is offered for exclusive use. It gives stable performance and long service life. | ||||

| Control System | 1. This system is assembled by hand-picked electronic components. All operations are set to be accomplished for only once. 2. The main circuit features multi-protection, such as excess current, excess load, short circuit, phase failure, and some others. Other useful functions include the polisher switch, lighting switch, emergency stop switch, the failure alarm, and more. | ||||

Recent Projects

-

- Large Size Bus Spray Booth in Peru Our company has undertaken to build a large-sized spray booth for the customers from Peru.

-

- Automotive Spray Booth in Canada Customers are pretty satisfied with our manufactured goods.

-

- Spray Coating Line Used for Industrial Parts in Cameroon Our company has been focusing on the spray coating line for more than two decades.

Reliable Paint Booth and Finishing System Provider

Talk with our teams for your applications

Get in Touch