- Home

- Products

- Spray Booth

- Spray Booth Heating Type

Spray Booth Heating Type

-

- Diesel Oil Burner of Spray Booth During the drying process, the oil nozzle of the burner can make fuel oil be atomized, which allows flame to be formed with the help of electric spark.

-

- Gas Burner of Spray Booth In the paint spraying process, the gas nozzle of the burner serves to eject the fuel gas. After electric spark ignition, flame can be formed.

-

- Radiant Heater of Spray Booth The high temperature far-infrared radiator with wide wavelength range is a high-end technology, which synthetically applies the thermal power, far infrared...

-

- Infrared Lamp Heater of Spray Booth The infrared lamp heater of spray booth is widely applicable for the industrial heating or drying process.

-

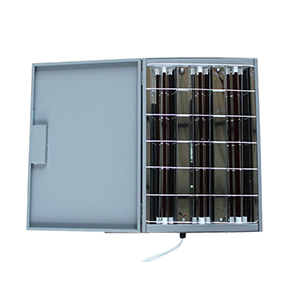

- Fin Heater of Spray Booth The fin heater of spray booth adopts a variety of materials including high-quality stainless steel, modified protactinium oxide powder, high-resistance electro-thermal alloy wire, stainless steel...

-

- Hot Water and Steam Heater of Spray Booth The hot water and steam heater of spray booth refers to the finned-tube air heat exchanger. It is mainly used for heating air in the drying system...

Video

We know what you need!

We are the leader for commercial and industrial paint, blasting and preparation equipment worldwide. Especially, we provide excellent solutions in the fields automotive, truck, transportation, aerospace, military and large equipment and woodworking markets.

Request A Quote